PRODUCT USES

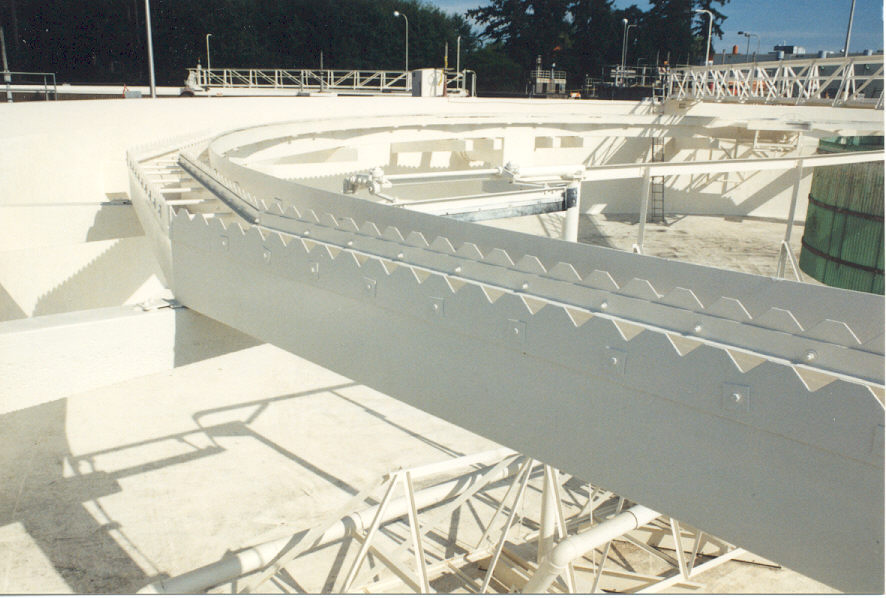

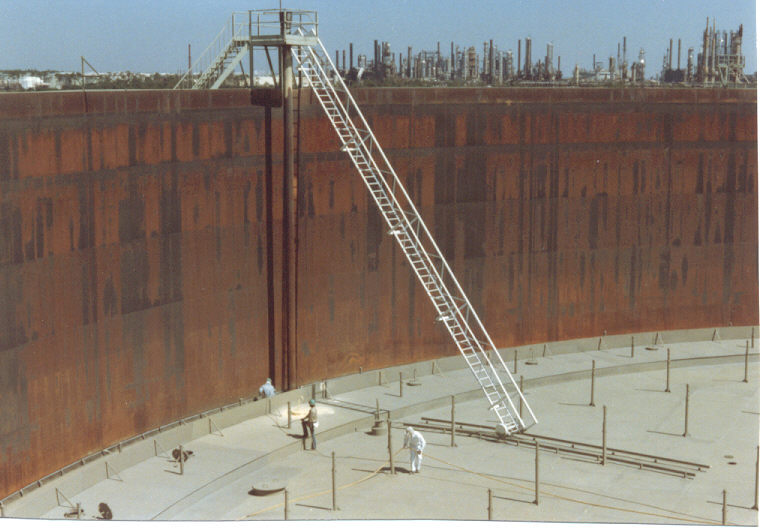

Recommended for structural steel, tank linings, vessels, equipment, pipe racks, storage tanks, towers, in chemical processing plants, pulp and paper mills, sewage and waste water treatment facilities, fertilizer plants, refineries, power plants, coal handling sites, mines and marine installations.

PRODUCT FEATURES

Self priming on steel.

Low Temp. Hardener will cure to 25°F.

Excellent chemical resistance to acids, caustics and many solvents.

Performs well over epoxy mortars and concrete surfaces.

Excellent as a secondary containment coating.

Excellent as a coating for internal tank linings.

Meets all EPA and other air pollution regulations. V.O.C. is less than one pound per gallon.

Outstanding impact, flexibility and abrasion resistance.

Capable for high film build, wraps around edges in one coat.

USDA Approved.

*Gloss will exhibit slight variation when brushed or rolled due to orientation of fillers. This will not affect

performance.

Details

| COLORS | White, Lt. Gray, Med. Gray, Dark Gray, Brick Red, Beige |

|---|---|

| FINISH | *60º GLOSS |

| VOLUME SOLIDS | 92% ± 2% |

| V.O.C. | .60 lbs/gal (72 GMS/Liter) |

| COVERAGE (Theoretical) | 1475 sq. ft. per gallon @ 1 mil |

| RECOMMENDED DRY THICKNESS | 5-12 dry mils @ 123-295 sq. ft. per gal. |

| PACKAGING | 5 gal and 1 gal kits |

| MIXING RATIO | 4:1 by Volume. 4 parts of Base (Part A) to 1 part of Hardener (Part B) |

| INDUCTION TIME | None |

| POT LIFE | @ 75°F: 2 hours (Regular Cure); 1 hour (Low Temp. Cure) |

| APPLICATION | Spray, roll or brush |

| APPLICATION TEMPERATURE | 50 – 120ºF (Regular Cure); 40 – 100°F (Low Temp. Cure) |

| RECOAT TIME | @ 75ºF: 7-8 hours (Regular Cure); 5-6 hours (Low Temp. Cure) |

| DRY SERVICE TEMPERATURE | 220ºF |

| THINNING | Up to 20% S-74 per mixed gallon |

| SHELF LIFE | Minimum 12 months |