Details

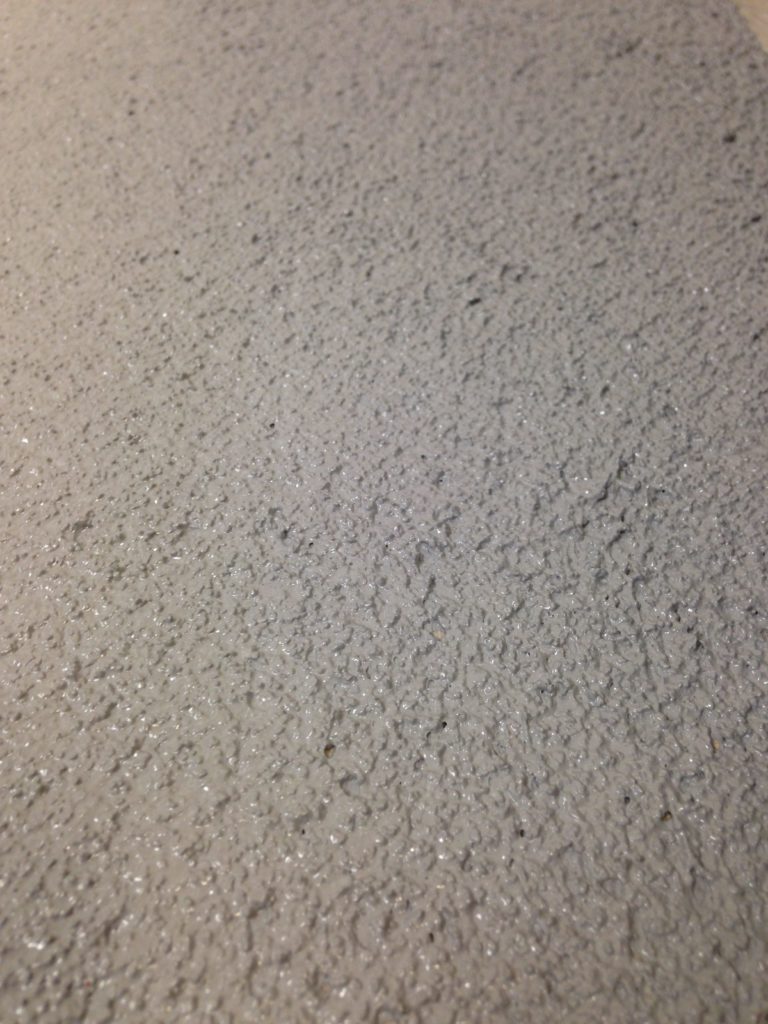

| COLOR | 182 Dark Gray, 231 Light Gray, Safety Yellow, Black (Other colors available on Special Order) |

|---|---|

| GLOSS | Gloss |

| VOLUME SOLIDS | 92 ± 2% |

| V.O.C. | 74 GMS/L (.61 LBS/gal) |

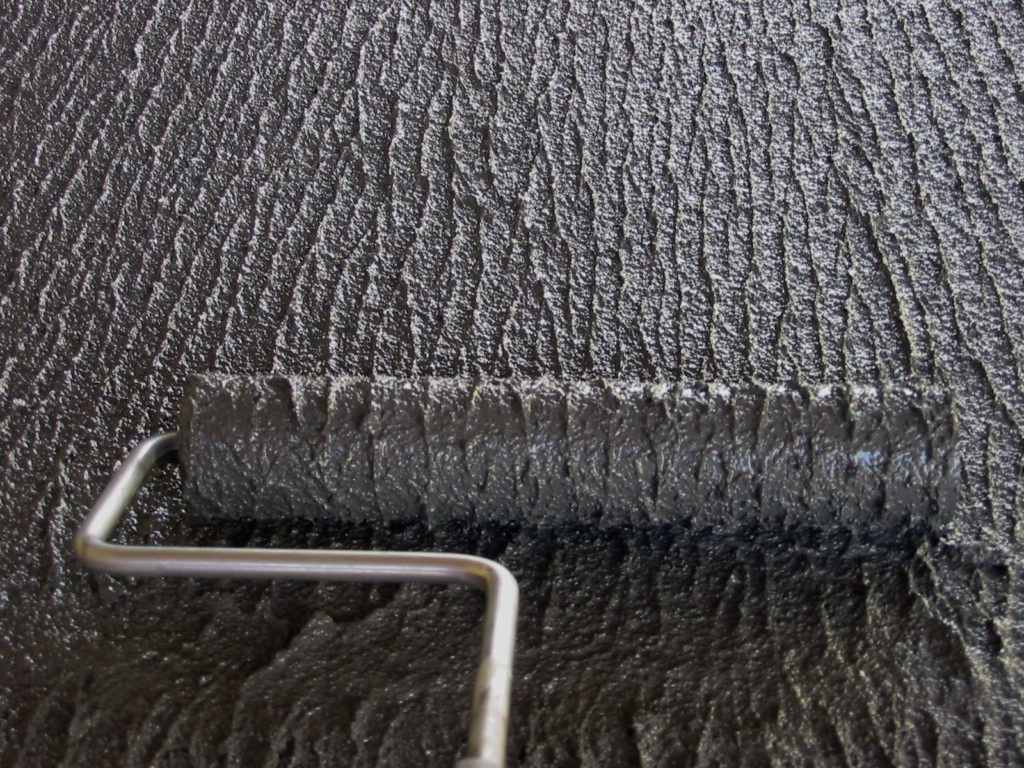

| THEORETICAL COVERAGE | Phenolic Core Roller – approximately 30-40 sq. ft. per gal. Trowel, squeegee – approximately 40-50 sq. ft. per gal. (coverage varies due to surface porosity and desired degree of non-skid |

| RECOMMENDED FILM THICKNESS | 1/32” – 1/16” |

| PACKAGING | 1 gal. and 5 gal. Kits |

| MIXING RATIO | 4:1 by volume. Mix 4 parts Base (Part A) to 1 part Hardener (Part B) |

| INDUCTION TIME | None |

| POT LIFE | @ 75ºF: 1-1/2 hours (Regular Cure); 1 hour (Low Temp. Cure) |

| APPLICATION | Phenolic Core roller cover, trowel or squeegee. |

| APPLICATION TEMPERATURE | 50-120ºF (Regular Cure); 40-100°F (Low Temp Cure) |

| DRY SERVICE TEPERATURE | 160°F |

| THINNING | 5-10% with SA-65, if necessary |

| CLEAN UP | SA-17 or S-74 |

| SHELF LIFE | Minimum 12 months |