PRODUCT USES

Recommended as a resin for restoration of concrete floors, sumps, drainage ditches, loading docks, tanks, ramps, storage silos, pump pads, and other concrete structures subjected to extreme chemical attack. PC-1875 is used frequently in secondary containment areas as a coating as well as a trowel down system. PC-1875 is also used as a resin with fiber glass reinforced systems. PC-1875 is used as a coating in “seed-in” systems.

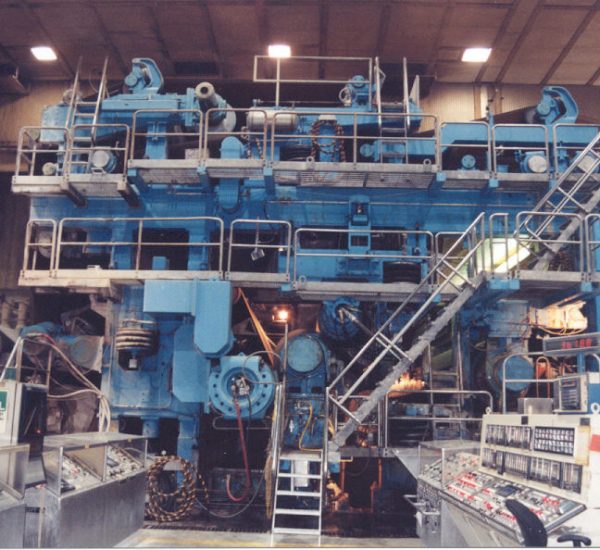

Ideal for most type services in chemical processing plants, mining operations, pulp and paper mills, sewage and waste water treatment facilities, fertilizer plants, petroleum refineries, electric generating stations, coal handling operations, food processing, etc.

PRODUCT FEATURES

Excellent resistance to acids, alkalis, salts, most industrial chemicals and many solvents.

Extremely tough with high wearing properties.

Excellent abrasion and impact resistance.

Good adhesion to concrete.

Self-leveling coating.

Meets USDA requirements.

V.O.C. compliant.

No solvent odor when applying.

Low temp cure – down to 40°F.

Will cure in damp conditions.

TEST DATA:

BOND STRENGTH: 350 psi fails per ACI test #59-43

COMPREHENSIVE STRENGTH: 10,000-12,000 psi per ASTM-C695

FLEXURAL STRENGTH: 14,500 psi per ASTM D-790

TENSILE STRENGTH: 8,800 psi per AST, D638

TENSILE ELONGATION: 4.6 per ASTM D-638

SHORE D HARDNESS: 82 per ASTM D2240

Details

| COLORS | Clear, Med. Gray |

|---|---|

| GLOSS | Gloss |

| VOLUME SOLIDS | 100% |

| V.O.C. | 16 GMS/L |

| RECOMMENDED FILM THICKNESS | Thin Film 10-40 mils or 40 -160 sq. ft/gal. |

| PACKAGING | 1 gal units and 4 gal units |

| MIXING RATIO | 3:1 by volume |

| POT LIFE | 20-30 minutes at 75°F |

| APPLICATION | Roller, squeegee, seed in, or trowel |

| APPLICATION TEMPERATURE | 50°F – 100°F |

| RECOAT TIME | 8-24 hours at 75°F |

| DRY SERVICE TEMPERATURE | 170°F |

| THINNER | Do Not Thin |

| SHELF LIFE | Minimum 1 year from date of manufacture |