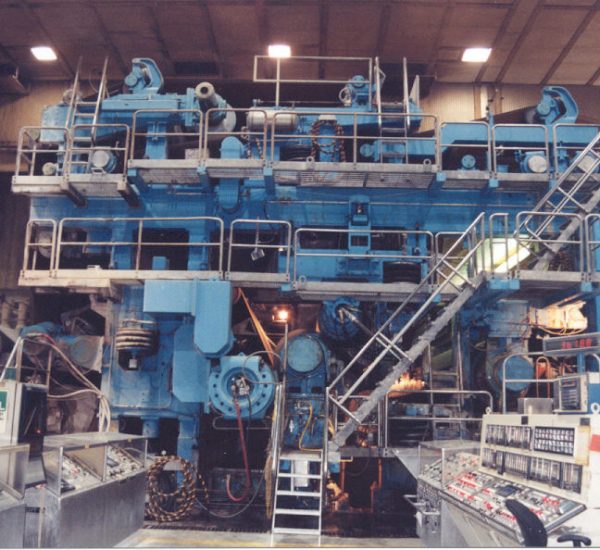

PRODUCT USES

Recommended for structural steel, tanks, vessels, equipment, pipe racks, etc., in chemical processing plants, pulp and paper mills, sewage and waste water treatment facilities, fertilizer plants, refineries, electric generating stations, coal handling sites, marine installations.

May be used as a coating on concrete floors in warehouses, tank pads, production areas, garages, and loading docks. Used as a coating on block walls and other cementitious surfaces.

PRODUCT FEATURES

Excellent chemical, abrasion, and impact resistance.

High film build, often used as two coat system.

Outstanding adhesion and “wetting out” properties.

Very low permeability-tight sealed film.

Low cost per dry mil.

Easily applied with airless or conventional spray.

Used on concrete or steel surfaces.

Available in wide range of colors.

Tile-like finish.

1 Values listed are for White, other colors may vary slightly

Details

| COLORS | Available in most industrial, safety colors, safety colors |

|---|---|

| GLOSS | High gloss |

| 1 VOLUME SOLIDS | 55 ± 3% |

| 1 V.O.C. | 3.40 lbs.or 407 GMS/L |

| COVERAGE (Theoretical) | (@ 1 mil Dry): 882 sq. ft./gallon at 1.0 DFT |

| RECOMMENDED DRY FILM THICKNESS | 3-4 dry mils or 220-290 sq. ft./gal. |

| PACKAGING | 5 gal, 1 gal Kits |

| MIXING RATIO | 4:1 by volume. Mix 4 parts Base (Part A) to 1 part Hardener (Part B) |

| INDUCTION TIME | 30 mins. |

| POT LIFE | 8 hours @ 75°F |

| APPLICATION | Spray, brush, or roller |

| APPLICATION TEMPERATURE | 50°F to 120°F |

| RECOAT TIME | 6-8 hours @ 75°F |

| DRY SERVICE TEMPERATURE | 200°F |

| THINNING | Up to 10% SA-65 |

| CLEAN UP | SA-17 or S-74 |

| SHELF LIFE | Minimum 12 months |