PRODUCT USES

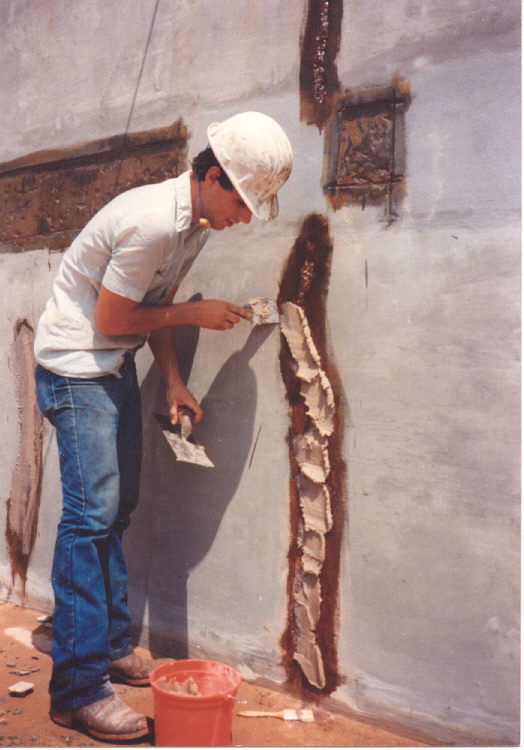

Recommended as an epoxy resurfacer or crack filler for restoration or concrete floors, sumps, drainage ditches, manholes, loading docks, tanks, ramps, storage silos, pump pads, and other concrete structures subjected to extreme chemical attack. Used as an epoxy filler to re-level and patch concrete floors, to patch “bug” holes, to build berms for containment of corrosive liquids, to fill badly exposed aggregate surfaces, etc.

Ideal for most type services in chemical processing plants, pulp and paper mills, sewage and waste treatment facilities, fertilizer plants, petroleum refineries, electric generating stations, coal handling operations, marine installations, etc.

PRODUCT FEATURES

May be applied up to 1″ thick when patching holes.

Excellent chemical, abrasion and impact resistance.

Easily applied with trowel, putty knife or spatula.

Applies up to ½ inch vertically.

Excellent for filling bug holes.

Used for leveling base plates and embedding bolts.

Non-toxic when cured.

Zero V.O.C.

Excellent for patching concrete in manholes and sewer pipes.

TEST DATA:

COMPREHENSIVE STRENGTH: 7,800 psi ASTM-D-695

FLEXURAL STRENGTH: 3,100 psi per

TENSILE STRENGTH: 2600 psi ASTM-D-638

WATER ABSORPTION: (24 hr ASTM-D-570) .5%

HARDNESS: (Shore D) 80

ASTM-D-790

Details

| COLORS | Gray |

|---|---|

| CURE TIME | 8 hours @ 75°F |

| VOLUME SOLIDS | 100% |

| V.O.C. | 0 GMS/L |

| COVERAGE (Theoretical) | 1.5 gal kit (neat) = 9.6 sq. ft. @ 1/4″ |

| RECOMMENDED THICKNESS | 1/8” – ½” |

| PACKAGING | 1.5 gallon units |

| MIXING RATIO | 2:1 by volume. Mix 2 part A Base with 1 part B Hardener |

| POT LIFE | 20-30 mins. @ 75°F |

| APPLICATION TEMPERATURE | 50°F – 100°F |

| RECOAT TIME | 8 hours minimum; 24 hours maximum @ 75°F |

| MAXIMUM DRY SERVICE TEMPERATURE | 150°F |

| THINNING | Do not thin |

| CLEAN UP | SA-17 or S-74 |

| SHELF LIFE | 12 months minimum |