PRODUCT USES

Recommended as a resin for Epoxy mortars or Epoxy toppings for restoration of concrete floors, sumps, drainage ditches, loading docks, pump pads, tanks ramps, storage silos, and other concrete structures subjected to chemical attack; in paper mills, chemical plants, sewage and waste water treatment plants, petroleum refineries, electric generating stations, food processing plants, textile mills, to name a few.

PC-1000 is used in commercial and institutional areas such as laboratories, warehouses, plant aisle-ways, mechanical equipment rooms, airports, and bridge decks.

PRODUCT FEATURES

Excellent abrasion and impact resistance.

Good chemical resistance.

USDA approved for use in food processing plants.

Trowels or screeds well.

Contains no solvents.

3-4 times stronger than concrete.

Low square foot cost.

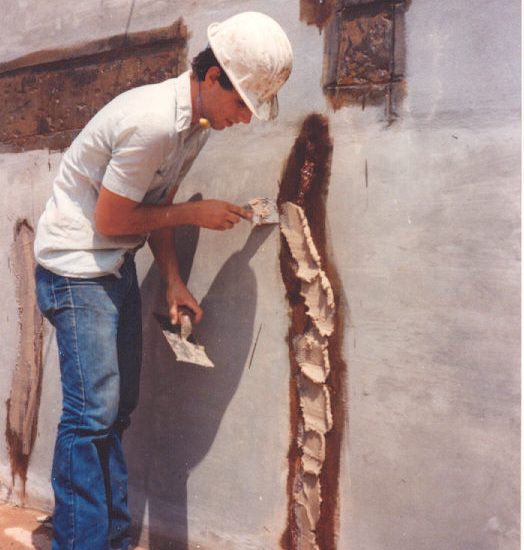

Can be used for epoxy mortars, epoxy concrete, slurry systems and vertical applications.

Good structural resin.

PC-1000 is available in both and slow cure formulas.

TEST DATA:

BOND STRENGTH: 350 PSI concrete failed per ACI test #59-43

SLOW CURE: 20 to 30 mins.

COMPRESSIVE STRENGTH: 11,000 psi – 12,000 psi per ASTM-C109-49

COMPRESSIVE SHEAR STRENGTH: 580 psi per Fed. Spec. MMM-B350A

FLEXURAL STRENGTH: 3200 psi per ASTM D-790

TENSILE STRENGTH: 9000 psi per ASTM D638-60

TENSILE ELONGATION: 3.8 per ASTM D638-60

SHORE D HARDNESS: 80 per ASTM D-2240

WATER ABSORPTION: .10% max per ASTM D 670-63

FLAMMABILITY: Self extinguishing per ASTM D-635-63

Details

| COLORS | Clear, Gray, Brick Red |

|---|---|

| VOLUME SOLIDS | 100% |

| V.O.C. | 5 GMS/L |

| COVERAGE | 1 gal. resin + 50 lbs. aggregate will cover approximately 24 sq. ft. @ 1/4’” |

| PACKAGING | 5 gal & 1 Bulk Resin |

| MIXING RATIO | 4:1 by volume |

| POT LIFE | @ 70°F: Regular Cure – 10 to 20 mins |

| APPLICATION | Trowel, squeegee |

| APPLICATION TEMPERATURE | 50° to 100°F |

| DRY SERVICE TEMPERATURE | 150°F |

| RECOAT TIME | 4-24 hours @ 75°F |

| SHELF LIFE | Minimum of 12 Months |