PRODUCT USES

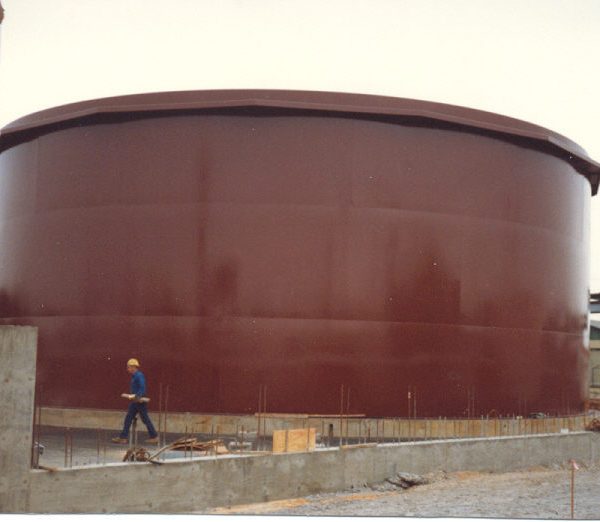

An excellent, fast recoat; sandable, production primer for fleet, rail, construction equipment, transportation equipment, and many OEM applications. An ideal epoxy primer for structural steel, tanks, vessels, equipment, to name a few. For use in chemical processing plants, pulp and paper mills, fertilizer plants, petroleum refineries, electric generating stations, coal handling operations, food processing plants and other industrial facilties where recoating in 60 minutes @ 90°F and 105 minutes @ 75°F is required for maximum productivity.

PRODUCT FEATURES

A high performance primer on properly prepared carbon steel, galvanized steel, and aluminum where:

Recoating in 90 minutes is possible for maximum productivity.

No induction time and longer pot life will improve productivity.

A smooth, sandable primer, at 3 mils DFT, for maximum appearance when topcoating is required.

A high build primer, up to 6 mils DFT, over abrasive blasted or power tool cleaned substrate is needed for

additional corrosion resistance.

Application by brush and roller, in addition to spraying, may be necessary.

Spray application with minimal dry spray is desired.

Application at temperatures as low as 35°F is needed. Will cure down to 20°F.

Details

| COLORS | Light Gray |

|---|---|

| FINISH | Flat |

| POT LIFE | 5 hours @75°F / 2.5 hours @ 85°F |

| VOLUME SOLIDS | 56 ± 2% |

| RECOAT TME | 105 min. @ 75°F (2 mils DFT) |

| COVERAGE (Theoretical) | 898 sq. ft. @ 1.0 mil DFT |

| APPLICATION | Spray, brush or roller |

| RECOMMENDED THICKNESS | 3 mils DFT @ 300 sq. ft. per gallon. Up to 6 mils DFT @ 150 sq. ft. per |

| APPLICATION TEMPERATURE | 35°F – 120°F |

| DRY SERVICE TEPERATURE | 220°F Max |

| MIXING RATIO | 2:1 by volume. Mix 2 parts Base (Part A) to 1 part Hardener (Part B) |

| INDUCTION TIME | None |

| PACKAGING | 15 gallon & 3 gallon units |

| THINNING | 5-15% SA-65 Reducer per gallon |

| V.O.C. | (2.8lbs./gal. / 335gmltr / low HAPS) |